1940

At the beginning of 1940, two entrepreneurs from Dačice decided to launch the joint production of fountain pens and on 27 August 1940, trade licence no. 15245/4 – VI/1940 was issued for the "selected profession: Mechanical factor trade: production of fountain pens and technical pencils - pressing and injecting of plastic."

1941

The production of fountain pens was launched in Dačice in January 1941. The first products produced involved a high ratio of manual labour. 20 employees were involved in production. The production experience obtained by the workshop from the manufacture of fountain pens formed the foundations for the establishment of the founders' future joint undertaking. The joint efforts of the two men resulted in a company which produced fountain pens and dealt with injection molding of plastic. The cooperation agreement was to remain valid until 31 December 1944. The joint undertaking's first product was a fountain pen entitled STENO. The pen's name is formed by the two entrepreneurs' surnames.

1945

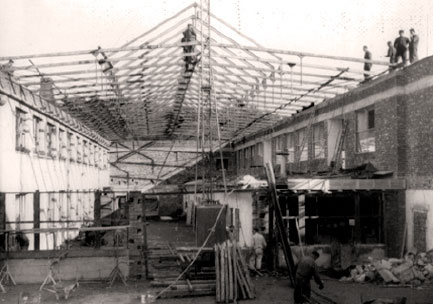

At the beginning of 1945, the two entrepreneurs split their company, strictly in line with the terms stipulated by the 1941 Agreement. In August 1945, one of the founders established a new company producing writing utensils, now under the brand name OMEGA, already based at the seat of the contemporary joint-stock company.

The then modern Vltavan injection moulding presses were used, on which the 50 employees could produce 300 fountain pens a day. The products displayed a high quality standard and soon became a success with both domestic and foreign customers. Sales mostly came from wholesale customers in Prague. Already 70 years ago, the company took care not only about the production economy but also about environmental friendliness. Plastic was the main raw material in the production of the fountain pen cases. Right from the beginning, the product left large quantities of residual material and pressing rejects. In order to prevent excessive waste, the redundant material was used to produce, or press, combs and pocket whistles, sometimes even with an integrated compass.

1948

In 1948, private companies with over 50 employees were nationalised by a decree of the Minster of Industry. The Dačice plant did not escape the effects of these political turnarounds.

The company was first submitted to national administration by Koh-I-noor, Pencil Plant, L & C. Hardtmuth n. p. České Budějovice, which was terminated as early as on 29 July 1948. The company was nationalised and the Dačice plant became an operational branch of the Centropen state-owned company, headquartered in Pardubice. It is worth mentioning that at the time of nationalisation, the company only had 49 employees. In order to allow the state to take control over the company, its staff count was temporarily and artificially increased to fifty.

.jpg)